Description

All About Our Grass Fed Swiss Cheese

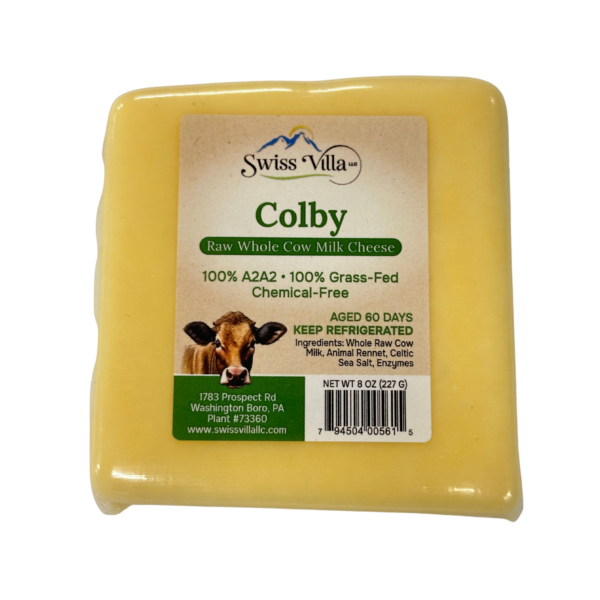

When it comes to dairy, you deserve the best. That’s why we offer grass fed Swiss cheese from chemical-free, small Amish/Mennonite family farms in Pennsylvania. Each chunk of our delicious grass fed Swiss cheese is made from 100% grass-fed A2/A2 cow’s milk, providing a host of nutritional benefits. We don’t rush the process. After 60 days of aging, it’s time to indulge in the irresistible flavor of our grass fed Swiss cheese.

Our Grass Fed Swiss Cheese Process

At Swiss Villa, we value transparency, starting with sharing the process by which we make our delicious grass fed Swiss cheese. Every step of the way, we ensure complete perfection, delivering grass fed Swiss cheese straight to your door.

First, 100% grass-fed cows are milked on small farms, giving us A2/A2 milk.

Once the cows are milked, the milk is heated to fermentation temperature; this preserves the natural health benefits of the milk by not pasteurizing it. The milk begins to ferment after we add starter cultures; real animal rennet is also added, helping the milk create curds. At this point, the milk begins to thicken and the curds separate from the whey.

Time to cut the curd! When curd knives (wires that cut the vat into quarter-inch cubes) are placed into the vat (or container that heats the cheese) they eventually become firm, releasing whey during the process.

Next, the curds are cut into smaller pieces and gently cooked to get rid of any excess whey plus ensure the curds are firmly set. Then the curds are pressed and molded to the desired shape.

We push the cheese curds further into the vat after the curds are heated and reach the correct consistency. Want to know another benefit of this process? After the whey has been fully drained from the curds, it makes a wonderful fertilizer for neighboring pastures and farmland.

Now, we cut large slabs of grass fed swiss cheese once the curds knit together in the vat. Then, as the cheese releases more whey, we rotate and stack each slab every fifteen minutes. This is called the cheddaring process, allowing the cheese to consolidate and become firm.

Finally, we can cut chunks of excellent cheese. As a last step, each chunk of cheese is aged to perfection for 60 days.

Success! Our raw swiss cheese has found its way from raw cow milk to chunks of flavorful cheese ready to be added to pasta or eaten plain. 🙂

Benefits Of Grass Fed Swiss Cheese

Curious about the health benefits packed into each chunk of our grass fed Swiss cheese? Let’s dig into a few of them!

Promotes Gut Health

Butyrate or butyric acid helps to support gut health. Because our grass fed Swiss cheese is made from A2/A2 milk, it has a high level of butyrate, creating a healthy gut barrier. What’s not to love about that?!

Higher Levels of CLA

Did you know that conjugated linoleic acid (CLA) provides a host of benefits, including helping to lose body fat and supporting immune health. Additionally, a study performed by Harvard School of Public Health revealed that high levels of CLA could help prevent heart attacks.

Dense Nutritional Value

When you choose our grass fed Swiss cheese, you are choosing higher levels of nutrition compared to non-grass fed cheese options. From higher levels of vitamins D, A, E, K2, and B to the presence of antioxidants and proteins, your health will receive a well-deserved boost!

Grass Fed Swiss Cheese Uses

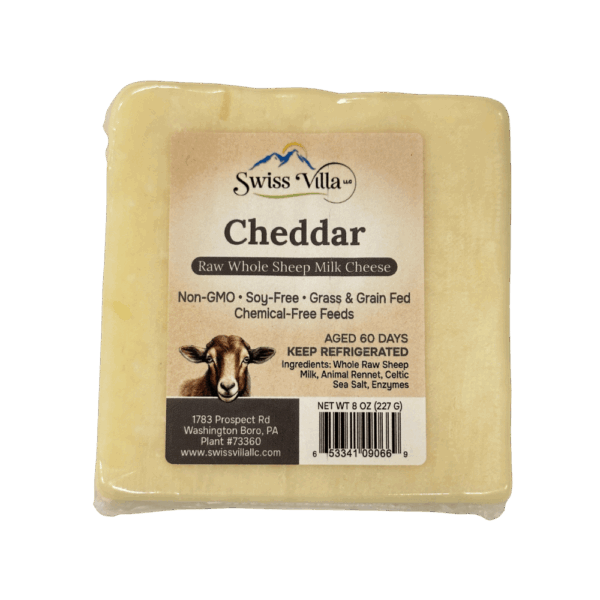

Do you love to diversify your food palette? We do, too! Grab a package of our grass-fed Swiss cheese and slice some for a charcuterie party for friends. Make a pot of nutritious chili and grill some sandwiches with our grass fed Swiss cheese to dip inside. Do you crave eggs for breakfast? Melt some grass fed Swiss cheese on top…you’ll be sure to enjoy this extra morning treat! Or, if you want to try some other flavors, check out our raw cheddar cheese, goat cheese curds, or raw feta cheese!

william wehner –

Gloria P. –

Delicious!

GAYLE F. –

High quality great tasting cheese